Reimagine Material Characterization with Setaram's Thermal Analysis, Calorimetry, Gas and Vapor Sorption solutions.

We offer a complete instrument range and customized solutions to industry and research professionals.

what we do – Thermal Analysis, Calorimetry and Gas Sorption Solutions

We partner with you to provide solutions for your material characterization challenges, solutions that can meet your future needs too. Our standard instruments address different measurement techniques, specifications and pricing. If you have specific needs our experts can work with you to develop a customized solution.

Our featured news

20% discount on our Setline DSC and Setline STA*

Categories: Product & Brand

Excerpt: Need a 20% discount on simple & powerful thermal analysis instruments ?

Webinar – Hydrogen

Categories: Webinar

Excerpt: Hydrogen is a clean source of energy, and it plays an important role in mitigating environmental challenges as well as facilitating the transition into a more sustainable future.

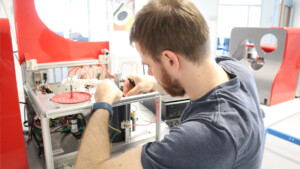

Robots designed by humans

Categories: Applications & Technologies

Excerpt: For more than 10 years, the KEP Technologies Group has been developing from A to Z autosamplers for its thermal analyzers, to meet the needs…

What sets us apart? – Our unique selling points

Setaram started its work in the most demanding field of high-end research, and expanded from there.

Our vast experience enables us to comprehensively address the most important customer benefits: Experimental Control, Instrument Versatility and Quality Results.

Need advice on which Setaram solution best meets your needs ?

Our certifications

KEP Technologies’ Organization System is designed to understand the customer’s preferences and needs. Customer satisfaction is one of our key values and we strive to achieve this through the alignment of our teams, quality and security processes, and technology throughout the product lifecycle.